Lean Enterprise Manufacturing Intelligence & Integration solution translates manufacturing data from the plant-floor into actionable intelligence for decision makers at the enterprise and business level.

Our Manufacturing Intelligence suite of solutions enable users to overcome business challenges, resulting in increased profitability, streamlined business efficiency and a strengthened loyalty to customers and vendors.

Our Solution addresses the needs to transform large amount of data generated from various related information systems into useful information in order to optimize the metallurgical production process. The solution is a blend of extensive knowledge of different industry, experience and state-of-the art technologies.

For large manufacturing operations with multiple plants even in different locations, Lean EMI&I solution addresses needs from planning to production, quality assurance, maintenance, asset and inventory management.

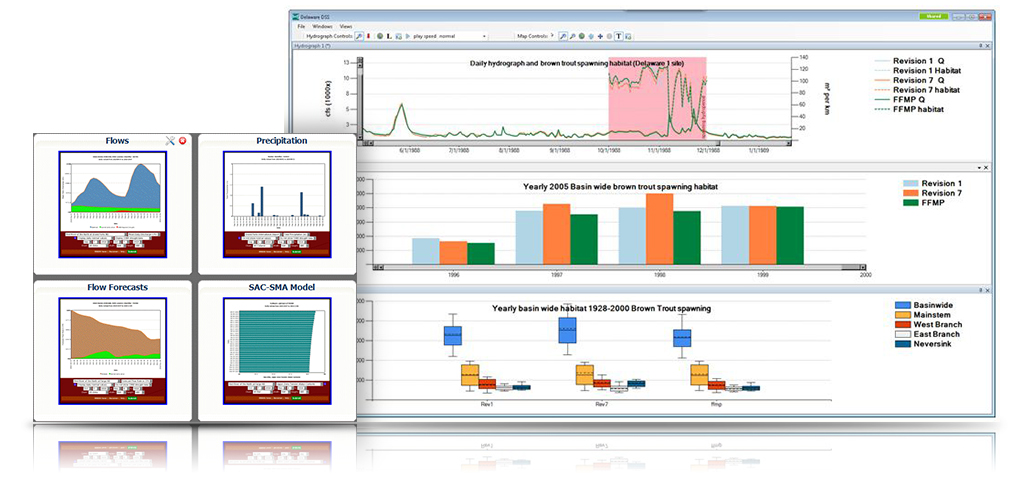

EMI&I uses existing data, along with estimated data points, to calculate a range of probable outcomes. This information allows a manufacturer to make more informed decisions. This analysis helps you find a solution when data is limited. Our solution consists of a data-intensive simulation whose objective is to analyze the behavior of a complex system, known as a scenario, by monitoring the impact of changes to a set of independent variables on a set of dependent variables.

Why EMI&I

- Adaptability and flexibility

- High level of Interactivity

- Ease of use

- Efficiency and effectiveness

- Complete control by decision-makers.

- Ease of development

- Extendibility

- Support for modeling and analysis

- Support for data access

- Standalone, integrated and Web-based

Features

- Support for decision makers in semi structured and unstructured problems.

- Support for managers at various managerial levels, ranging from top executive to line managers.

- Support for individuals and groups. Less structured problems often requires the involvement of several individuals from different departments and organization level.

- Support for interdependent or sequential decisions.

- Support for intelligence, design, choice, and implementation.

- Support for variety of decision processes and styles

Benefits

- Improves efficiency and speed of decision making activities

- Increases the control, competitiveness and capability of futuristic decision making of the organization

- Facilitates interpersonal communication

- Since it is mostly used in non-programmed decisions, it reveals new approaches and sets up new evidences for an unusual decision

- Helps automate managerial processes