PlantWIKI™ is a powerful application for the plant information management system built on a highly robust and extremely fast process historian. The fundamental functionalities include acquisition, visualization, analysis, archiving and reporting of information from a wide variety of control, plant and business systems. PlantWiki™ plays a pivotal role in a manufacturing enterprise’s application architecture for creating a common repository of plant information that can be effectively leveraged in enterprise and supply chain management applications.

PlantWiki™ can hold a complete model of a whole plant or an enterprise encompassing mission-critical process variables, equipment effectiveness, energy consumptions, best practices, productivity levels, under-performance notifications and much more in contextual rich format.

PlantWiki™ include process historians, data reconciliation, operations activity management, condition-based maintenance, energy management, performance calculations & monitoring, inventory management, material tracking, mass/energy balance, and production performance control.

PlantWiki Brochure Download

What PlantWiki offers! Get the brochure...

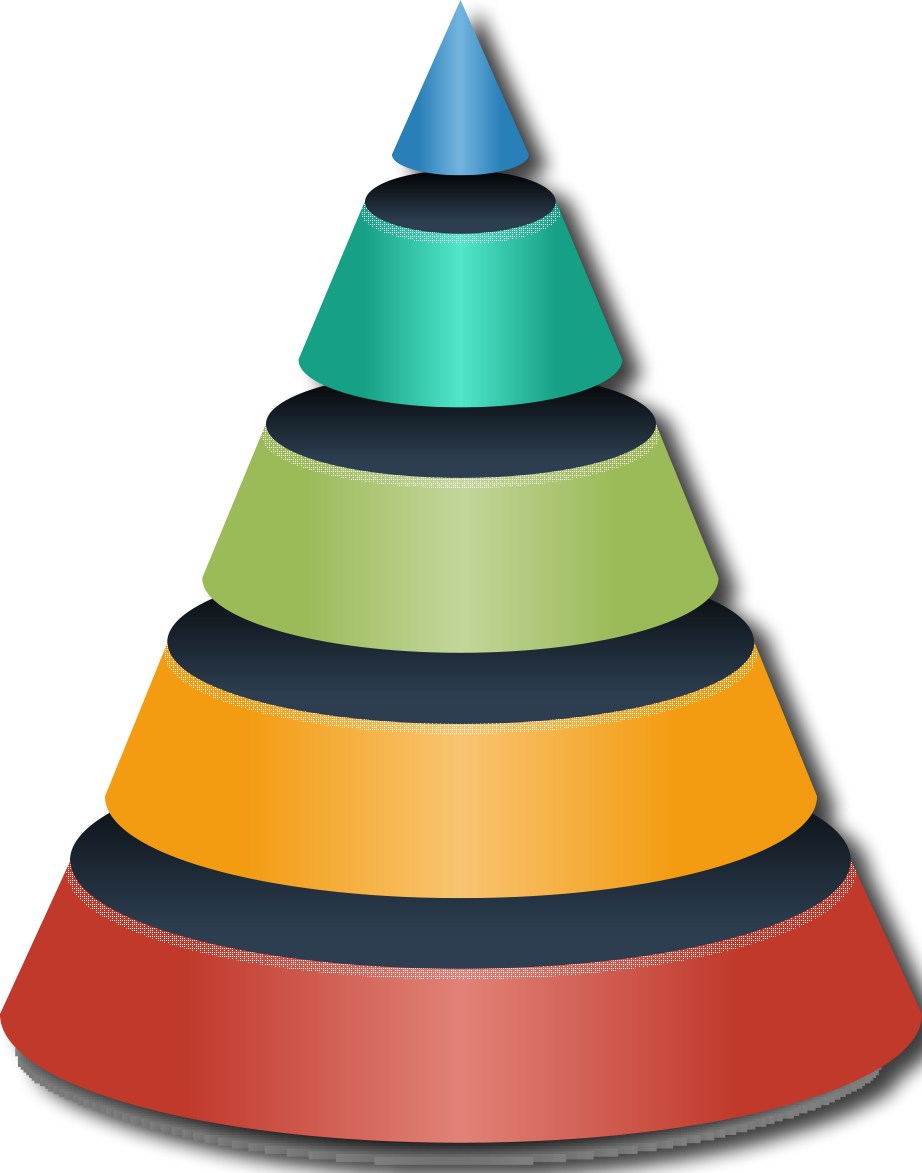

Enterprise Manufacturing Intelligence (EMI) – Totally Automated Plant

Enterprise Resource Planning (ERP), Enterprise Asset Management (EAM), Business Intelligence (BI) etc.

Plant Information Management System (PIMS), Energy Management information System (EMIS), Simulation Systems etc.

PLC, DCS, SCADA, HMI, MES, LIMS

Instruments, Sensors, Actuators, Analyzers etc.

-

Enterprise Integration & Manufacturing Intelligence

Enterprise Manufacturing Intelligence (EMI) – Totally Automated Plant

-

Business Applications Level

Enterprise Resource Planning (ERP), Enterprise Asset Management (EAM), Business Intelligence (BI) etc.

-

Data Management Level

Plant Information Management System (PIMS), Energy Management information System (EMIS), Simulation Systems etc.

-

Control Level

PLC, DCS, SCADA, HMI, MES, LIMS

-

Plant Floor Level

Instruments, Sensors, Actuators, Analyzers etc.

First Step Towards Sustainability

You can only manage what you measure

Agility Meter

Sustainability is a business imperative without which no organization can survive in a competitive global marketplace. The key to sustainability lies in the fact that how quickly do we realize the need and get on feet to implement it at all levels of our organization

Verify how Kaizens/improvement initiatives are impacting the EBITDA/Profitability. Sustain them by making part of optimized procedures

Develop detailed use cases for identified opportunities focusing on both process value financial benefit; gain Process and Finance support

Transform Real-Time & Historized data into actionable information. Extract Benchmarks & Best practices by the implementation of advanced data mining engines

Collection & Historization of information from disparate data sources like PLCs, DCS, SCADA, Database, 3rd party applications & manual data

-

Validate & Sustain

Verify how Kaizens/improvement initiatives are impacting the EBITDA/Profitability. Sustain them by making part of optimized procedures

-

Define & Execute

Develop detailed use cases for identified opportunities focusing on both process value financial benefit; gain Process and Finance support

-

Analyze & Benchmark

Transform Real-Time & Historized data into actionable information. Extract Benchmarks & Best practices by the implementation of advanced data mining engines

-

Aggregate

Collection & Historization of information from disparate data sources like PLCs, DCS, SCADA, Database, 3rd party applications & manual data

PlantWiki™ Rationale

- Right Information to the Right People at the Right Time – Every Time

- Accelerate root cause analysis and corrective action

- Leverage skills and lower costs by delivering remote information to the experts

- Improve decision support, operating performance, cost efficiencies, and customer service

- Establish one version of truth throughout the enterprise.

MANUFACTURING INTELLIGENCE & INTEGRATION

- Overall Equipment Efficiency (OEE)

- Production Planning & Performance analysis

- Identification of Bechmarks and potential best practices

- Full blown dashboards with multidimensional analysis. Enterprise Modeling & Advanced KPI engine

CONDITION MONITORING & RELIABILITY OPTIMIZATION

- Automatic Run Hour calculation & posting to PM/CMMS/EAM systems

- Condition monitoring and automatic work order generation in maintenance systems.

- Comprehensive Downtime Analysis supplementd with downtime reasons & underlying causes

- Analysis & Reporting of MTBS, MTTF & MTTR

PROCESS ANALYSIS & DIAGNOSTICS

- Process Screens tailored for different operational & maintenance roles

- Extensive Trending & Charting funcitonalities - Click & Trend

- Alarm Analytics to improve O&M effectiveness

- Comprehensive reporting on Process, Production, QC & Energy

QUALITY ANALYSIS & MANAGEMENT

- QC data integration through standard interfaces with analyzers, LIMS and spreadsheets.

- Statistical Quality Control using diverse SQC library.

- 100% visibility into Quality sampling & frequency.

- Transparent collaboration between QC & CCR.

ENERGY MANAGEMENT, ANALYSIS & MODELING

- 360 0 analysis of WAGES (Water, Air, Gas, Electricity & Steam).

- Interactive Energy Dashboarding & Reporting

- Heat & Mass Balancing

- Modeling of energy with influencing factors using Regression & adavanced data mining algorithms

EMISSION MONITORING & ANALYSIS

- Integration with Environmental analyzers.

- Online Monitoring of Particulate NOx, SO2 & CO.

- Tailored Environmental Dashboards to calculate KPIs like C02/ton etc.

- Data Mining functions to reduce process upsets thereby reducing emissions.

Robustness & Scalability

- Fault Tolerant Architecture

- Scalable to 10 million process variables and more than 10,000 VTQs/sec

- Scalable to Corporate wide Historian using the Top Notch Technology of Distributed Intelligence

- Extensibility & Scalability on the fly – No downtime required

- Fast Data Retrievals – Years of data within seconds

Data Visualization

- Full Blown Web Clients

- Industry Standard Process Screens, Real time & Historical Trending and Alarms & Events

- KPI Calculations and Intuitive Dashboarding

- Smart Data Mining – One Click Analysis

- Multi-Layer Visualization – Cluttering/De-Cluttering, Zooming & Panning

- Geospatial Navigation and Analysis

- Excel Add-on Reporting using Industrial Standard OPC HDA and OLEDB connectivity

- Collaboration with Mobile Technology – PDAs, Tablets etc

Advanced Data Management

- Full Access to OPC HDA Process Functions

- Regression, CUSUM and SPC

- ISA 18.2 and EEMUA 191 Alarm Management & Analytics

- Event Management 21CFR11

- Historical Trends & Alarms Annotation

- Export of Historical Trends to CSV

- Connectivity with 3rd party OPC HDA and A&E Servers for Distributed Repository

Advanced Archive Management

- Time & Event Based Data Archiving to Secondary Locations

- Hard-disk Space Based Data Archiving to Secondary Locations

- State-of-the-art data compression algorithms

- Portable history backups. Link in place: Enables the users to link up with the history backups at different servers without copying operation.

- Archiving to Hardware & Software Storage Area Networks

Enhanced Security Model

- Role Based Granular Security

- OPC UA Tunnelling for DMZ and Firewalls

- OPC Server & Client Access Control Mechanism

- Windows Domain Authentication

- User Action Logs & Probing

Compliance & Interoperability

- Six Way OPC Compliance (DA, HDA and A&E)

- OPC UA – Server & Client

- ISA-95

- Event Management 21CFR11

- ISA 18.2 and EEMUA191 Alarm Management & Analytics

- Passed Interoperability Tests with Yokogawa ExaOPC, Emerson Delta V, Siemens PCS 7, Honeywell Experion, Invensys Foxboro (IA) and ABB Industrial IT – To name a few

- SAP Netweaver, IBM Maximo and AspenTech Certified Interfaces

- SOAP, OLEDB & ODBC Compliant

Supported Platforms for Server

- Windows Server 2012

- Windows Server 2008 R2

- Windows Server 2003 R2

Supported Platforms for Client

- Windows 8

- Windows 7 Professional (32-bit or 64-bit)

- Windows XP Professional SP3 (32-bit or 64- bit)