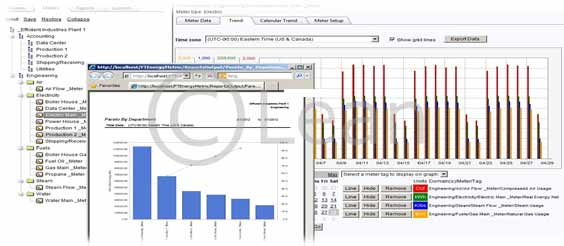

With the real knowledge at your fingertips you can use the information to speed fault finding processes and to aid sound business decisions. Lean engineers will work in tandem with you to understand your requirements and present the information in a suitable, meaningful and comparative fashion so that trends are clear and discrepancies are obvious. A variety of formats can be used to present the data including graphs, contour plots, mimic diagrams and histograms, and the data can be presented on different machines, lines, shifts or products.

With Advanced Data Historians making knowledge and insight available to management personnel, most companies see real business benefits.

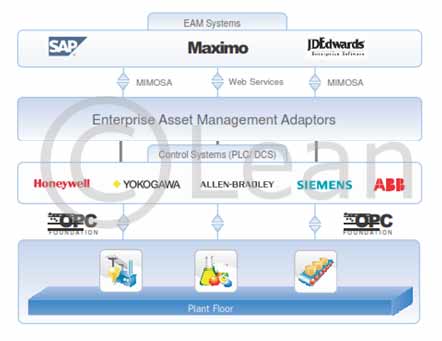

Lean offers expertise in the design and integration of the following Advanced Data Historians and Databases:

| OSISoft PI | Microsoft SQL |

| PlantWiki | Oracle |

| Honeywell PHD | AspenTech InfoPlus.21 |

| ICONICS Hyper Historian | Wonderware InSQL |

| ABB Knowledge Manager | Citect Ampla |