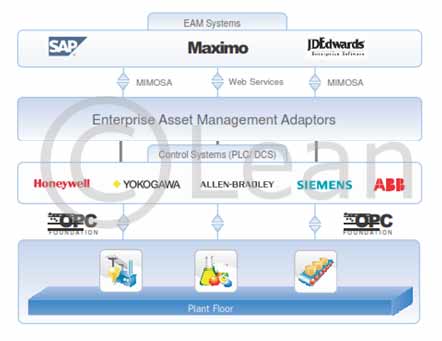

Enterprise Asset Management is an integrated plant operation solution that enables companies to operate plants more smoothly by keeping equipment running at the lowest cost. Integrating different software with enterprise asset management software is a critical step that companies need to take in order to get a handle on expenses, and to be able to execute better management on an ongoing basis.

Lean Automation’s Enterprise Asset Management Integration solution enables communication between EAM/CMMS systems and provides a mechanism for Real time Condition Based Monitoring. We provide computerized maintenance management systems (CMMS) and other maintenance management solutions as part of our Enterprise Integration offering, all to help increase your uptime and reduce your maintenance costs while decrease longevity of equipment. This system could help you to reduce your total cost of ownership. Our platform-independent approach ensures that we deliver the best solution for your operations, without bias for any particular technology.

Benefits

- Shift from reactive to proactive maintenance through CBM.

- Workload reduction on current workforce resulting in greater productivity, less turnover, cost savings and co-worker development.

- Reduced need for regulatory inspection

- Reduced Workforce: Eliminates the need for plant technicians to manually collect meter readings and then manually enter the results into the CMMS / EAM systems

- Intelligent Inventory Management

- Improved reliability would uncover additional capacity as redundant standby equipment could be put to use in production.

- Implementation of Reliability Centered Maintenance (RCM) strategies which involves On-Condition and Complete maintenance within Schedule, Locating failures and One Time Change in System.

- Coherent Real-time Data collection

- Comprehensive maintenance database creation, including significant Alarms & Events in their particular order and time.

- Improved overall skill level and technical knowledge

- Enables maintenance supervisor or manager to optimize planning with better visibility into actual equipment condition

- Reduction in unplanned downtime by achieving greater asset reliability and availability

Features

Our EAMI solution is compliant to open industry standards including OPC DA, A&E, HDA, and UA and has the following technical functionalities

- Complete Enterprise Asset Information

- Real-Time Condition Based Monitoring

- Work Order Generation through historian and Alarming

- Analytics (EEMUA 191 Based Analysis Tools)